Tripodmaker maintenance

Cleaning

- clean v-grooved wheels with a plastic brush

- clean v-rails the wheels ride on

- clean feeder teeth

- connect via usb to computer

- in Printrun, open port /dev/tty.usbmodem1421 and use baud rate 115200

- vacuum away the dust

- vacuum the rod ends too. They collect tiny metal particles that are attracted to the magnet.

- clean hot-end

- check if Bowden tube doesn't have internal resistance

- clean build plate with hot water

Moving parts

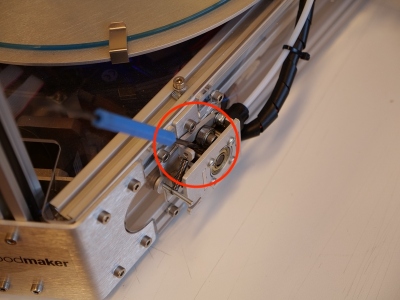

Keep the wheels and magnetic bearings free of dust. These black components are made from POM and attract dust. Preventing dust to accumulate elongates their lifetime.

Tightening eccentric nut. No need to loosen the hex bolt first.

Check your carts on wobble after a while. If the carts are loose on the track, you can tighten the eccentric nut in order to remove the cart wobble. The carts must run smooth. If you over tighten the eccentric nut, you will need to use allot of force to move the cart and it will seem you have “hick-ups” during the sliding maneuver.

Nozzle and hot-end

Make sure that the nozzle and hot-end are cleaned when loaded with plastic residues. To clean of the nozzle, simply heat it until the plastic gets sticky, and use a printed cube to peel of the sticky plastic.

Clean drive gear

The drive gear is not designed for serviceability, but with these steps it is not too painful.

- Connect Tripodmaker to Repetier-Host using the 2 usb extension cables.

- Connect the USB cable to the Renkforce USB Hub. Don't connect directly to the back of the iMac. For some reason only the USB hub connection works.

- In Repetier-Host, set the printer settings:

- Port: look for the 'usbmodem' entry (or look for the change in the port listing when plugging in the cable).

- Baud Rate: 115200

- Stop Bits: 1

- Parity: None

- Transfer Protocol: Auto

- Receive Cache Size: 63

- Timeout: 40s

- Use ping pong communication: not ticked

- Firmware sends OK after error: not ticked

- Click 'Home All' to test the connection.

- Heat up the extruder to 180°C. This is approx the lowest temperature needed to be able to turn the extruder motor. Colder, and the software gives a warning to avoid cold extrusion.

- Clean the drive gear slots you can reach with a sharp pick. Insert the pick just in front of the idle bearing. Be patient and do one slot of the gear at a time. Only ±4 slots are in reach.

- In the print panel of Repetier-Host, extrude

2,5mm (the speed is not important). This rotates the extruder gear just enough to clean the next section - Keep cleaning until the whole gear is free from plastic.