Making tool holder-holders

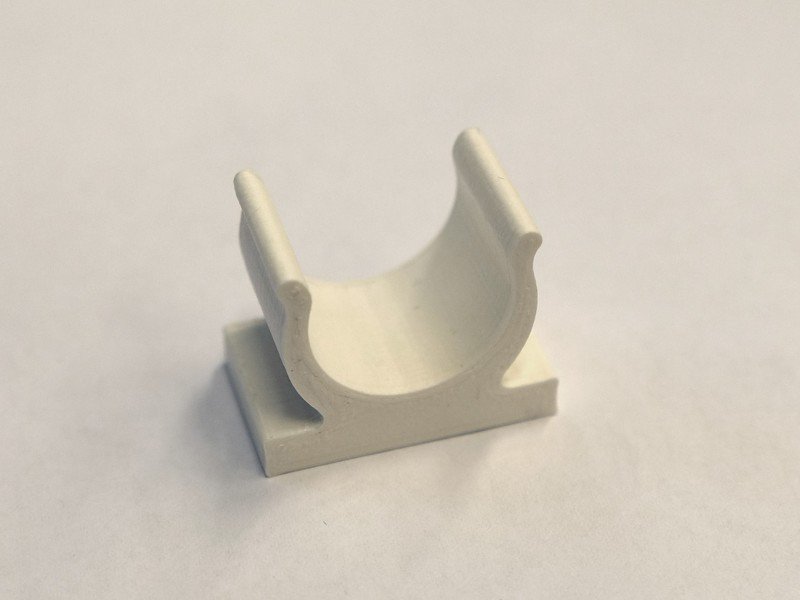

To stop the SK11 milling bit tool holders from rolling away, I decided to make some holders for them. I started with a 3D printed clamp-section to test a snap-fit.

It did fit surprisingly well on the first try. Note that if you want to keep tension on the object, PLA is not a good material. It will loose clamping strength over time.

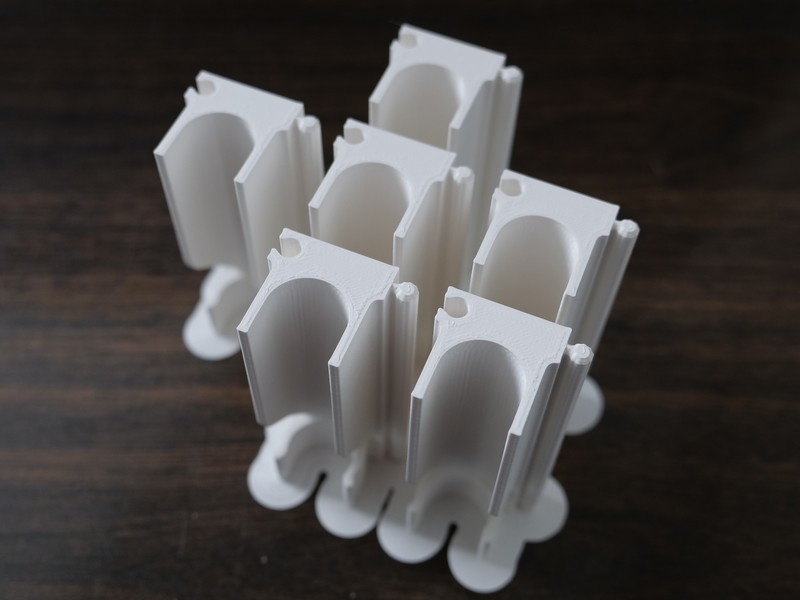

A first version of the holder. I added a guard for the sharp milling bits and connector elements left and right. I wanted to make the holder modular, so multiple holders could be attached to one another. They didn't fit on first try.

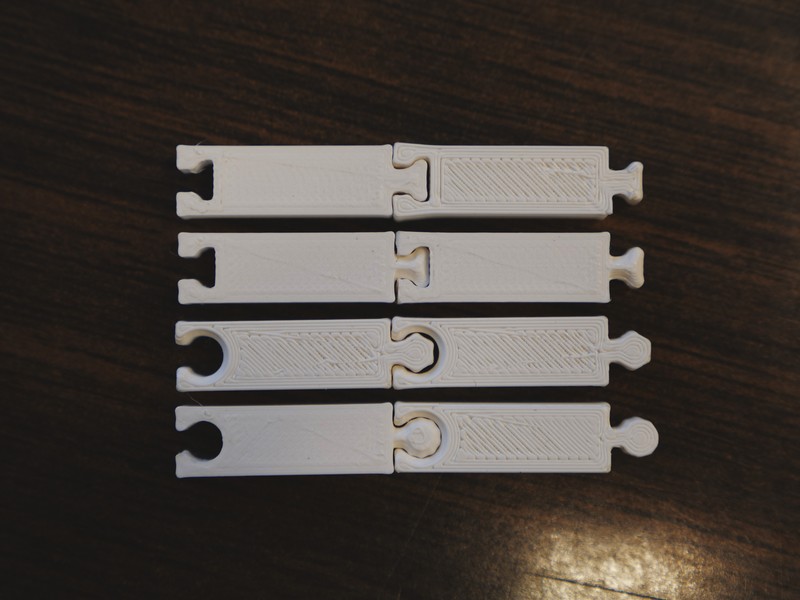

Focussing on the connector element, I tried to gradually increase the tolerances on the connector. The dovetail shape prints a little sloppy due to the sharp corner. I settled on a 10-sided polygon.

Clamping tolerances: the tool holder part that will be clamped is 17mm in diameter. The inner circle of the clamp is 16,9mm. The neck of the connector has 0.45mm tolerance on each side. The polygon has a 0.25mm tolerance on it's radius.

The pieces are designed to be printed vertically. This prints slightly slower, but more can be printed at once.

The holders attach fairly easily while still having a firm connection. All the pieces need to be printed on the same machine. Even different printers from the same brand and model have slighty different results. This causes the friction fit to be too loose or too firm.