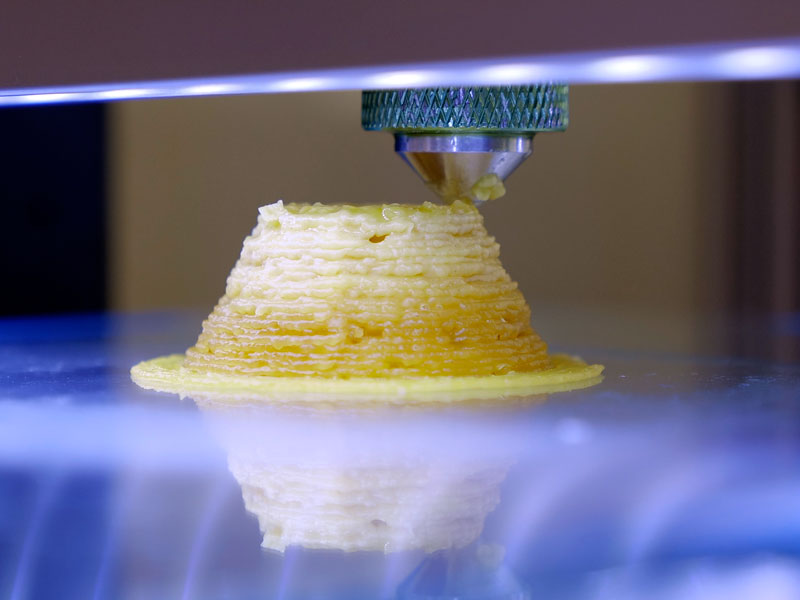

Testing out the influence of temperature on the consistency of beeswax.

Vanessa Müller tested the effects of different temperatures and nozzle sizes when printing with beeswax. During this test, the syringe was heated to 35°C and the beeswax extruded as a paste through a 1mm nozzle. The skirt halfway and the rim at the top were results of missing steps on the Z-axis. The lines look nice and tidy but they can be peeled away easily. At these temperatures they didn't stick together well.

Step by step the temperature was raised. In this test, the syringe was heated up to 60°C which was the highest temperature Vanessa tested. At that point, the wax was mostly liquid. Even then it wanted to clump together. We thought that a thinner nozzle opening and smaller layer height might create a more consistent extrusion, but that was not the case. The extrusion was very unstable, with some parts of the wax fully liquid and other parts blocking the nozzle. The color gradient shows the temperature of the wax: light when exiting the syringe, and darkening to the regular wax color when it slowly cools to room temperature.